FRP Gratings

FRP Gratings Manufacturer & Supplier in India

Rawji Exports is a leading manufacturer and exporter of high-performance FRP gratings in India designed for industrial flooring, walkways, trench covers, offshore platforms and infrastructure projects. Our Fiber Reinforced Plastic gratings offer superior corrosion resistance, lightweight strength and long service life compared to traditional materials.

Established in 1962, Rawji Exports supplies customized grating solutions suitable for chemical plants, wastewater treatment plants, marine applications, power plants and heavy industrial environments across India and export markets.

Explore our complete product range including FRP Gratings, FRP Doors and FRP Roofing Sheets.

Specifications for FRP Gratings

- GRP/FRP Gratings are produced by wet moulding and hot curing in a heated mould.

- The reinforcement consists of continuous fibreglass rovings in alternating layers, so the loads are distributed evenly in all directions.

- Regularly Moulded GRP Gratings have a polyester resin matrix.

- Glass content is approximately 35%. Standard colours are green, yellow or grey, other colours are available according to RAL.

Advantages of FRP Gratings

- Corrosion And Chemical Resistance.

- High Strength To Weight Ratio.

- Electric And Thermal Non Conductive.

- EMI/RFI Transparent.

Looking for customized FRP gratings for your industrial project? Our technical team can help you select the right grating based on load capacity, chemical resistance and application requirements.

Contact UsGully Gratings

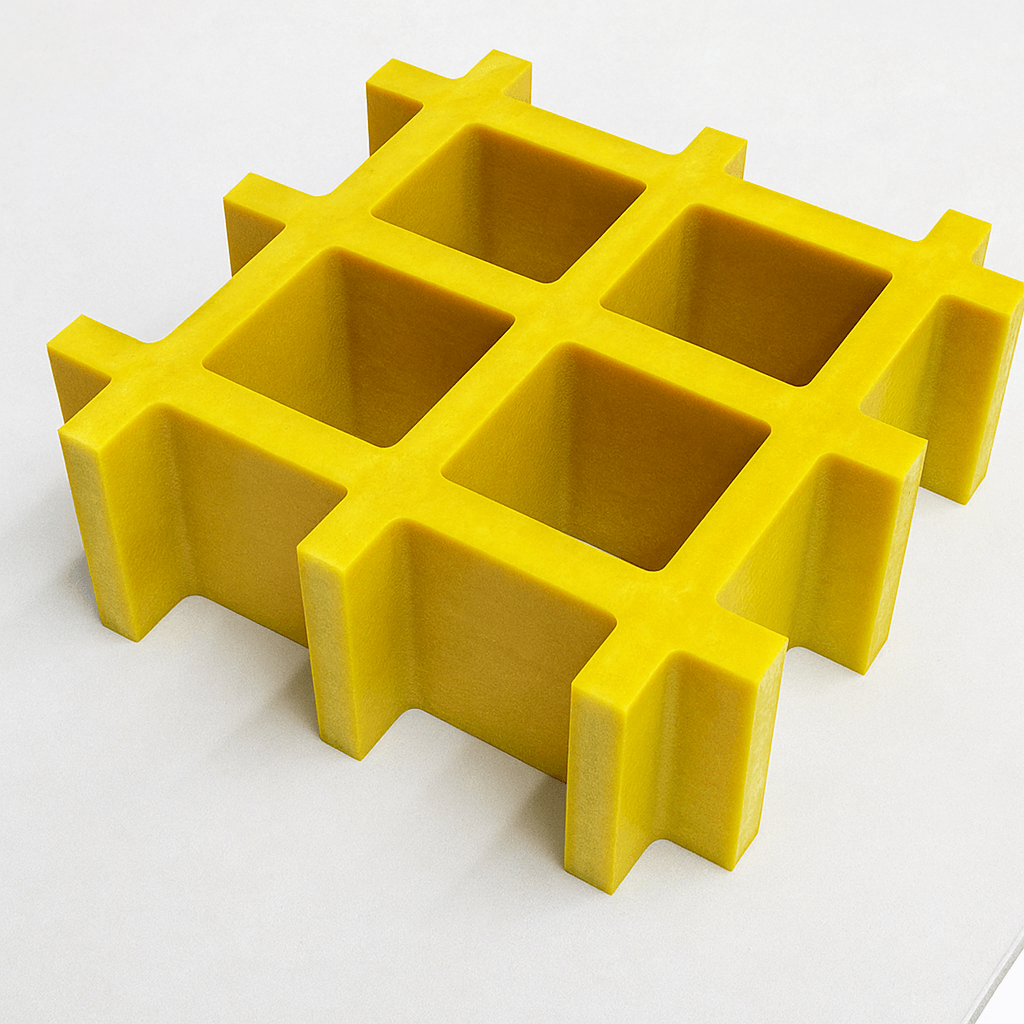

Moulded Grating

Gully Grating

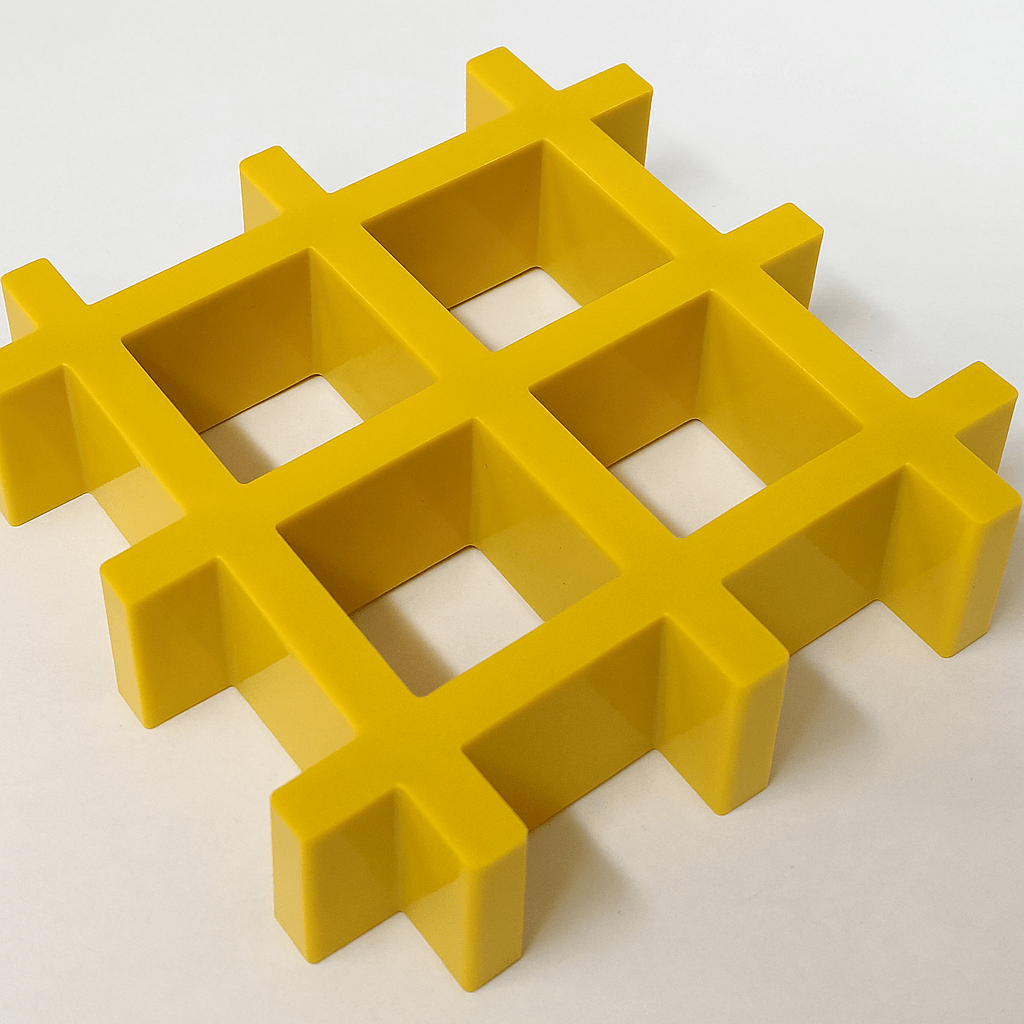

Pultruded Grating

Square Grating

Comparision with Conventional Material

Features

- Corrosion Resistance

- Strength

- Weight

- Electrical Conductivity

- Thermal Conductivity

- EMI/RFI Transparency

- Fabrication

- Life Cycle Cost

- Environmental Impact

Rawji FRP

High

High

Low

Low

Very Low

Yes

Easy

Low

Low

Steel

Low

High

High

High

High

No

Easy

Moderate

High

Aluminium

Medium

High

Low

High

High

No

Moderate

Moderate

High

Timber

Low

Low

Medium

Moderate

Low

Yes

Easy

High

Low

Material Details

COMPOSITE MATERIAL

Composites are materials made up of at least two different component materials, neither of which is suitable for structural use on its own, but when combined, they form a sturdy and firm material.

FRP / GRP MATERIAL

Fibre Reinforced Plastic / Glass Fibre Reinforced Plastic is a composite material made of a polymer matrix reinforced with fibres. These fibres are typically fibreglass, carbon, or aramid, while the polymer is usually an epoxy, vinylester, or polyester thermosetting plastic.

RAW MATERIAL OF FRP

- Glass Fibres: Provide stiffness and resist tensile and compressive loads.

- Resin: Transfers load between fibres and bonds them together.

- Other Additives: Provide fire retardancy, electrical insulation, etc.

RESIN SYSTEM – Polyester

- Most commonly used; good mechanical, electrical, and chemical balance.

- Can be modified for flame retardancy or self-extinguishing behavior.

- Excellent resistance in weak acid/alkali environments.

- Max operating temp: 80°C (basic grade).

RESIN SYSTEM – Vinyl Esters (VE)

- Combines benefits of polyester and epoxy resins.

- High strength and excellent acid/alkali resistance at high temps.

- Good thermal and electrical insulation.

- Max operating temp: 90–150°C.

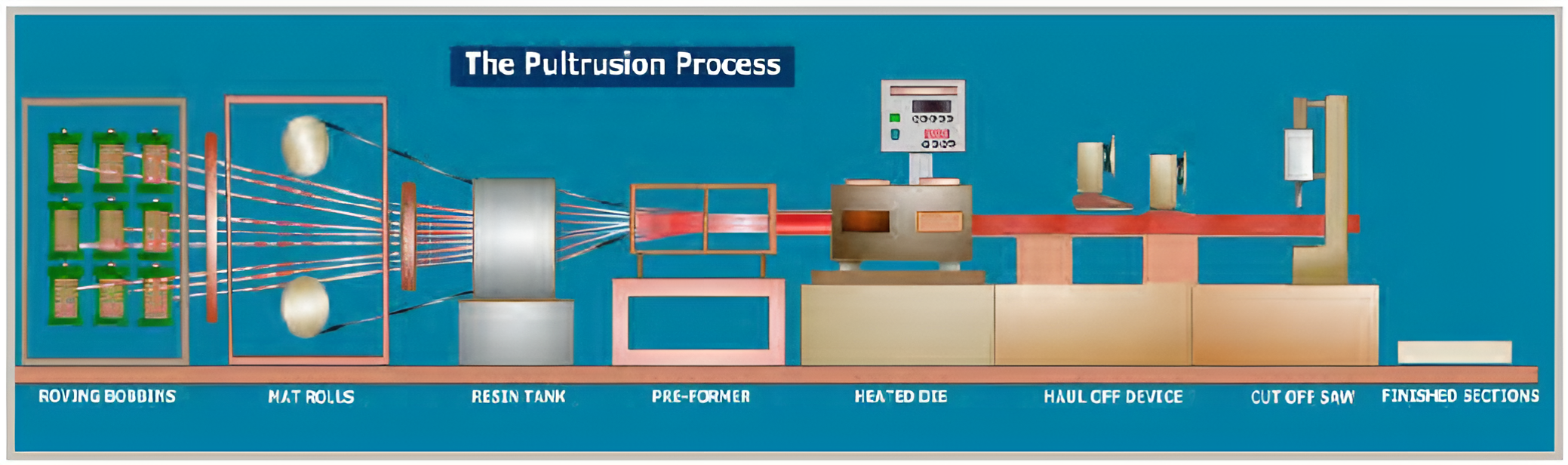

Pultrusion Process

Pultrusion is the process of pulling fibreglass reinforcements such as mats and

strands through a proprietary resin and heated die. The result is a specific complex profile that can

be cut to any length. This process offers speed and consistency making it the best method for

producing high-volume linear fiberglass products that require constant cross sections.

Pultrusion refers to pulling plastic raw material through a preformer. This

production method is particularly suitable for tubes, profiles etc. reinforced with continuous fibres,

involving pulling of impregnated fibres via preformers providing the form as, simultaneously, the

plastic is hardened with heat (thermoset) or cooled until solid (thermoplast).

Moulding Process

GRP/FRP Gratings are produced by wet moulding and hot curing in a heated mould. The reinforcement consists of continuous fibreglass rovings in alternatinglayers, so the loads are distributed evenly in all directions. Regularly Moulded GRP Gratings have a polyester resin matrix. Glass content is approximately 35%. standard colours are green, yellow or grey, other colours are available according to RAL.

Resin System For Gratings

| Resin Type | Resin Base | Description | Flame spread rating ASTM E84 |

|---|---|---|---|

| Type IFR | Isopthalic Polyester | Industrial Grade Corrosion resistance & fire retardant | Class 1, 25 or less |

| Type I | Isopthalic Polyester | Industrial Grade Corrosion resistance in acidic environment | Non fire retardant |

| Type V | Vinyl Ester | Superior Corrosion resistance & fire retardant | Class 1, 25 or less |

| Type P | Phenolic | Low smoke and superior fire retardant | Class 1, 5 or less |

Accessories

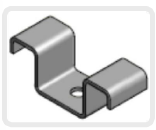

M CLIP - FOR FIXING MOULDED GRATING WITH SUPPORT STRUCTURE (Ordering Code: ASMGC-38)

C CLIP - FOR FIXING PULTRUDED GRATING WITH SUPPORT STRUCTURE (Ordering Code: ASPGC-I-00)

C CLAMP - FOR FIXING TWO MOULDED GRATING PANELS (Ordering Code: ASMGC-C-25/38)

PULTRUDED GRATING CLAMP - FOR FIXING TWO PULTRUDED GRATING PANEL (Ordering Code: ASPGC-I-01)

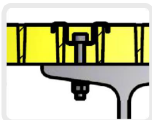

Types of Surface Finish of Grating

Concave Top: Suitable for wet & oily conditions

Inbuilt Grit: A quartz grit finish applied in the mould during manufacture

Applied Grit: A quartz grit sealed with a tough, long wearing epoxy coat

Chequered Plate/Grit Top

Industrial Applications of FRP Gratings

Composite gratings are widely used across heavy industrial sectors because of corrosion resistance, durability and low maintenance performance.

Chemical & Process Industries

Installed in chemical plants where steel structures suffer corrosion damage. Composite gratings provide long service life in aggressive chemical environments.

Wastewater Treatment Plants

Used in sewage and wastewater facilities for trench covers and walkways due to resistance against moisture, acids and gases.

Marine & Offshore Platforms

Marine environments demand materials that resist salt corrosion while maintaining structural reliability and reducing maintenance cost.

Power Plants & Refineries

Industrial flooring gratings improve worker safety by offering anti-slip surfaces and electrical insulation.

Trusted FRP Gratings Manufacturer Since 1962

With over six decades of composite manufacturing experience, Rawji Exports has established itself as a reliable industrial gratings manufacturer supplying fiberglass composite solutions across infrastructure, chemical, marine and energy sectors.

Frequently Asked Questions – FRP Gratings

FRP gratings are widely used for industrial flooring, trench covers, walkways, offshore platforms and chemical processing plants.

Yes, FRP gratings provide excellent resistance against chemicals, salt water and harsh industrial environments.

Yes, gratings can be manufactured in customized sizes, colours and load bearing capacities as per project requirements.

Supplying industrial gratings across Mumbai, Pune, Delhi, Chennai, Bangalore, Hyderabad, Ahmedabad and PAN India infrastructure projects.